NASA partners with 3DCERAM Sinto for advanced ceramic 3D Printing in space missions

In partnership with Jacobs Area Exploration Group, the Marshall Area Flight Heart, representing NASA, has shifted focus to superior supplies analysis, awarding a contract for the C1000 Flexmatic 3D Ceramic Printer to 3DCERAM Sinto, Inc.

This contract brings a brand new frontier for ceramic 3D printing as utilized in area. The C1000 Flexmatic—one of many machines that may produce giant elements and totally dense elements alike—will probably be essential in fabricating small and huge elements and supporting the event of supplies that may maintain the tough situations of area.

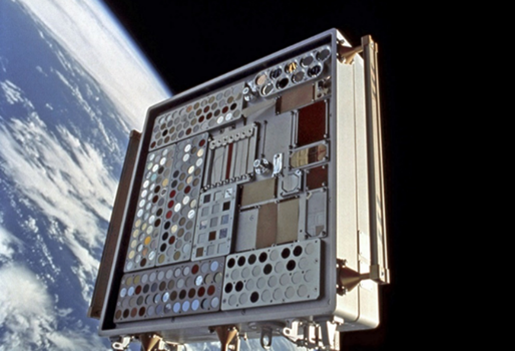

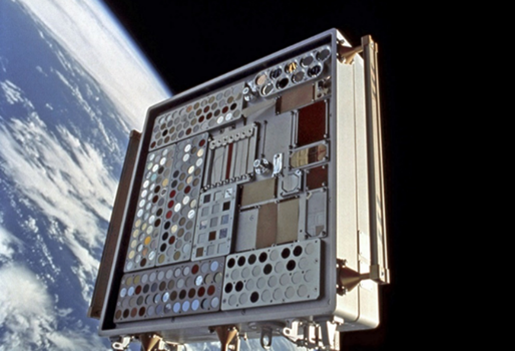

This preliminary part will probably be a part of the Supplies Worldwide Area Station Experiment (MISSE) program, a significant check mission performed to check the sturdiness of supplies in area. 3DCERAM Sinto will produce 20 pattern elements dispatched to ISS subsequent 12 months.

These will probably be mounted on a panel outdoors the ISS and undergo excessive situations in outer area for six months, enabling NASA to check the consequences attributable to zero gravity, photo voltaic radiation, and different space-related situations on the ceramic supplies.

In that respect, the MISSE program performs an enormous position in NASA‘s final aim of utilizing supplies in area automobiles and different extraterrestrial purposes. The outcomes of those checks will present immense data about how properly 3D-printed ceramics carry out in area and assist produce flight-worthy scorching constructions and warmth shields.

The truth that the C1000 Flexmatic can print small and huge elements on its 320 mm × 320 mm platform permits NASA to find intensive purposes. This shut collaboration underlines how Additive Manufacturing is more and more key to area exploration as 3DCERAM Sinto turns into part of NASA’s community of companions.

If 3D-printed ceramics may be built-in efficiently into area missions, it’s going to flip a brand new leaf in how supplies will probably be created and used outdoors Earth. This partnership proves that 3D printing know-how opens a brand new doorway for even harder and extra resilient supplies to be deployed in area.

Creator: Nagarjun M

Keep in mind, you possibly can submit free-of-charge job alternatives within the AM Trade on 3D ADEPT Media or search for a job through our job board. Be certain to observe us on our social networks and subscribe to our weekly e-newsletter: Fb, Twitter, LinkedIn & Instagram! If you wish to be featured within the subsequent problem of our digital journal or should you hear a narrative that must be heard, ensure that to ship it to [email protected].